FAQs - Spot size & focusing

- What is the effective spot size of the fiber optic probe?

-

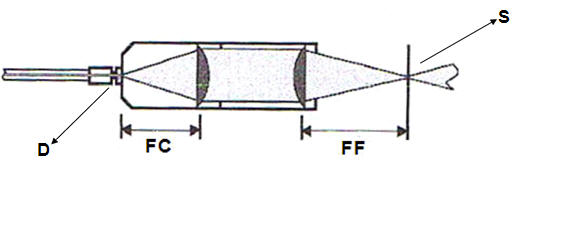

The basic optical assembly in our probe consists of three components:

The Delivery Fiber (with a core diameter D)

A Collimating Lens (with focal length FC)

A Focusing Lens (with focal length FF)

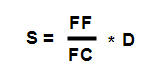

The effective spot size (S) is determined by the above three components, as follows:

In case of our probe,

D = 100¦Ì ; FC = 4.6 mm ; FF (Standard) = 4.6 mm, which results in the spot size diameter to be 100¦Ì.

- Can the spot size be changed?

From the discussion above, in principle it is possible to change the spot size diameter by varying the delivery fiber diameter, the collimating lens focal length or the focusing lens focal length. However, from an instrumentation perspective, changing the focal length may also involve changing the diameter of the lens, and hence the whole design of the probe.

At the present time, we have the option of changing only the focusing lens focal length (FF) from 4.6 mm to a value higher. In other words, we can increase the spot size from 100 ¦Ì to a value higher. Lenses are available in different focal lengths, and we have used up to 21 mm focal length. Please call us for details.

- Why are coating measurements difficult?

- As described above, the spot size is only about 100 ¦Ì. Thinking of this as a focusing sphere itis critical that this 100 ¦Ì is a part of the coating to be measured. Especially if the coating thickness is less than 100 ¦Ì there is a possibility that the focusing sphere will completely miss the sample, and focus on the substrate itself (especially if the coating of interest is transparent).

- How do you get around this problem?

- We typically use a translation stage and mount our probe on it such that it moves in very small steps, along the z-axis. We then use the focus mode in the measurement options, on our software to locate the exact position where the probe focuses on the coating.